Electroslag Welding (ESW)

The main application area of the Electroslag process is the joining of plates approximately 10 mm thick and above, although plates in excess of 50 mm thick are more likely to be welded using this process. Carbon steel, low alloy steels and austenitic stainless steels are the only materials weldable with the Electroslag process.

The name electroslag is derived from the fact that the process uses 10 electrically conducting slag.

Welding is carried out only when the plates are in the vertical*, or near vertical position. A square cut joint is always used. Once welding has started it must be carried out to completion because restarts produce defective areas. The process is used on ships, pressure vessels, steel castings, structural steel etc.

ESW

*Welding is performed in 20 the vertical-up position.

For welds up to 75 mm thick, the ESW process uses less weld metal and 90% less flux than SAW; plates 75-300 mm thick are welded at 600-1200 mm/hr. Angular distortion is eliminated.

Electroslag welds are relatively defect free, slag entrapment, porosity and lack of fusion defects are almost non-existent. Electroslag welds normally require post-weld heat treatment especially on the thicker materials, due to the resultant coarse grain structure.

A flat characteristic power source is required. A typical 3 mm diameter wire will require 40 volts and 600 amps.

Method of operation

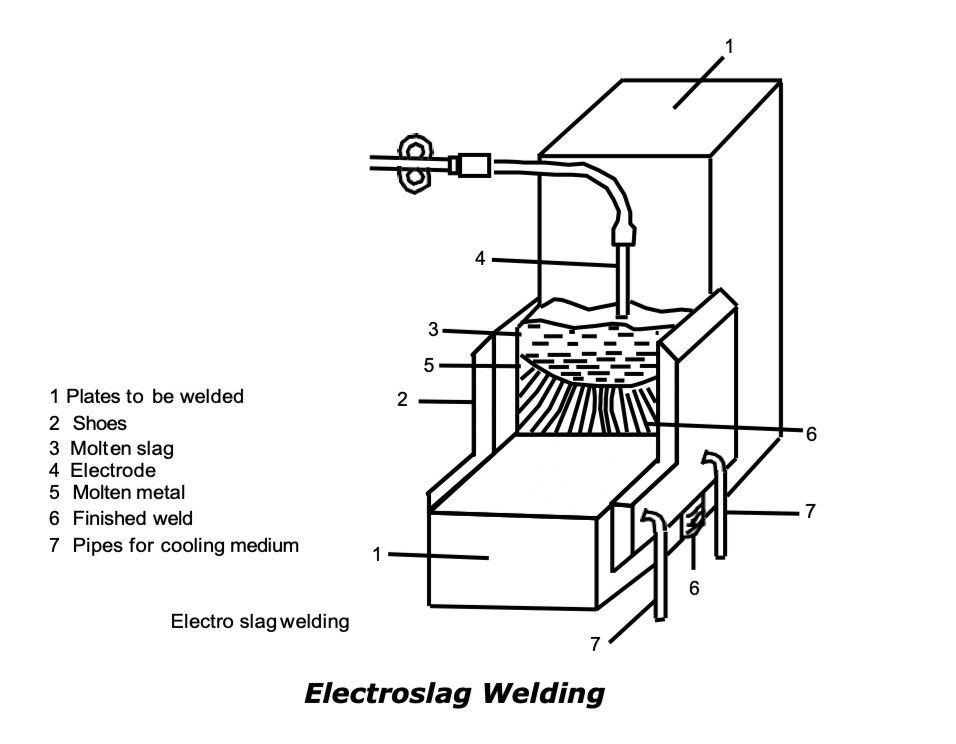

ESW is a fusion welding process which uses the combined effect of current and electrical resistance to produce a conducting bath of molten slag which melts both the filler wire(s) and the surfaces of the workpieces to be welded. The weld pool is also shielded by this slag which covers the full surface of the weld and rises as the weld progresses up the joint.

The process is initiated by an arc, usually struck on wire wool type material, which is itself laid onto a starting block which supports the initial liquid material.

Powdered flux is placed at the bottom of the joint, this is liquified by the arc which is then extinguished by the now conductive, though highly resistive, molten slag. All the current now passes through this molten slag, the resistance creating heat.

In order to retain the molten mass of flux and weld metal, water cooled copper shoes are fitted either side of the joint and walk or slide progressively upwards as the welding proceeds.

Process options

Two variations of ESW are in general use. These are the non-consumable guide and consumable guide processes.

1. Non-consumable guide process

In this technique, one or more wires, depending upon metal thickness, are fed into the molten slag through a guide or guides which are constantly maintained approximately 75 mm above the molten slag. One electrode is required for each 60 mm of metal thickness. If an oscillating or pendulum technique is used this can be increased to 120 mm. This method of ESW is suitable ranging from 10 to 500 mm thick.

2. Consumable guide process

for material thicknesses With this method, filler metal is supplied by both the electrode and its compatible metal guide. The metal guide directs the wire to the bottom of the joint and extends for the full weld height which may be as much as 10 metres. The guide is consumed as welding progresses upwards and can provide from 5 to 15% of the filler metal. One electrode/guide is required for each 60 mm of weld metal but this increases to 150 mm if an oscillating technique is used. The consumable guide technique is suitable for material of unlimited thickness.